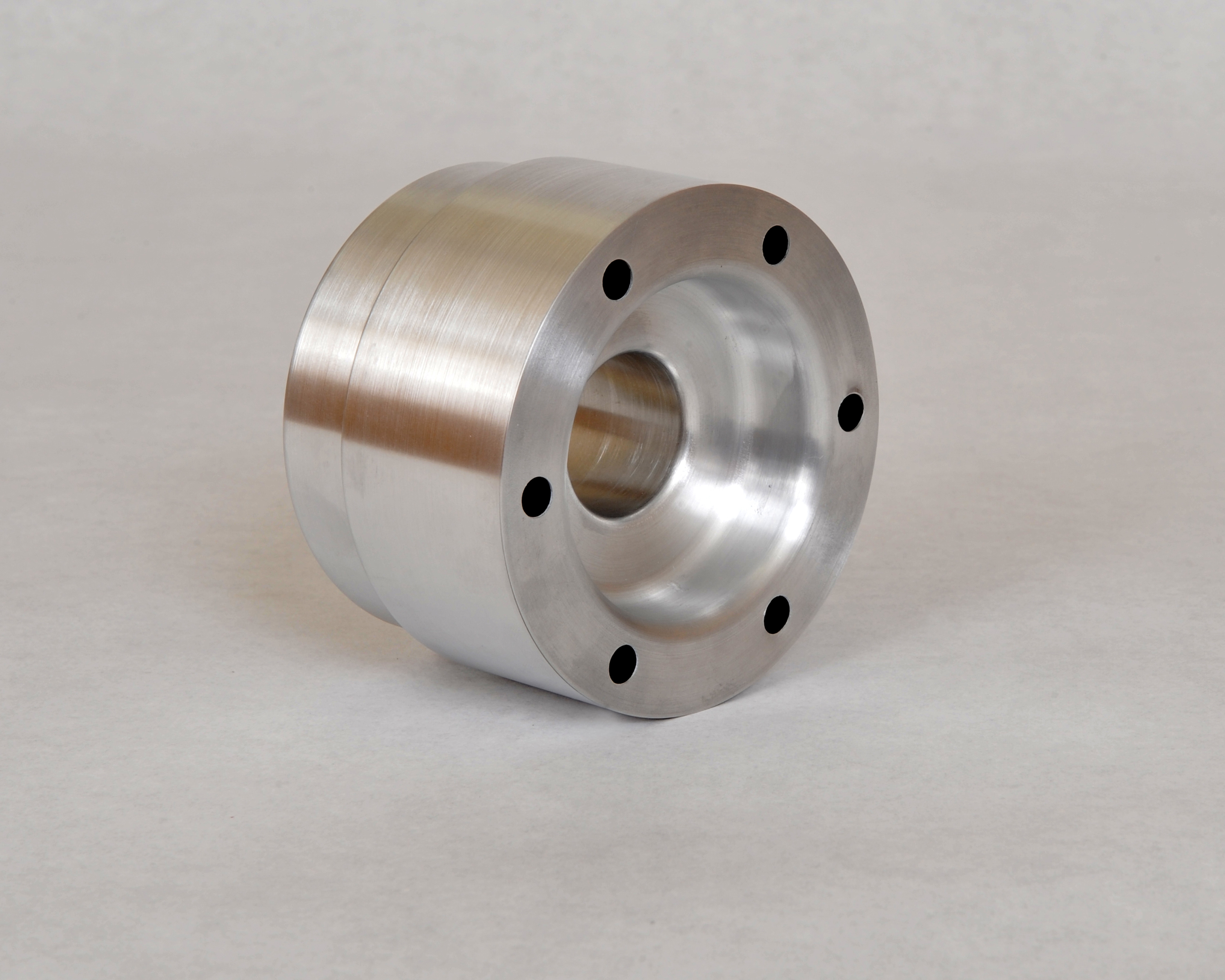

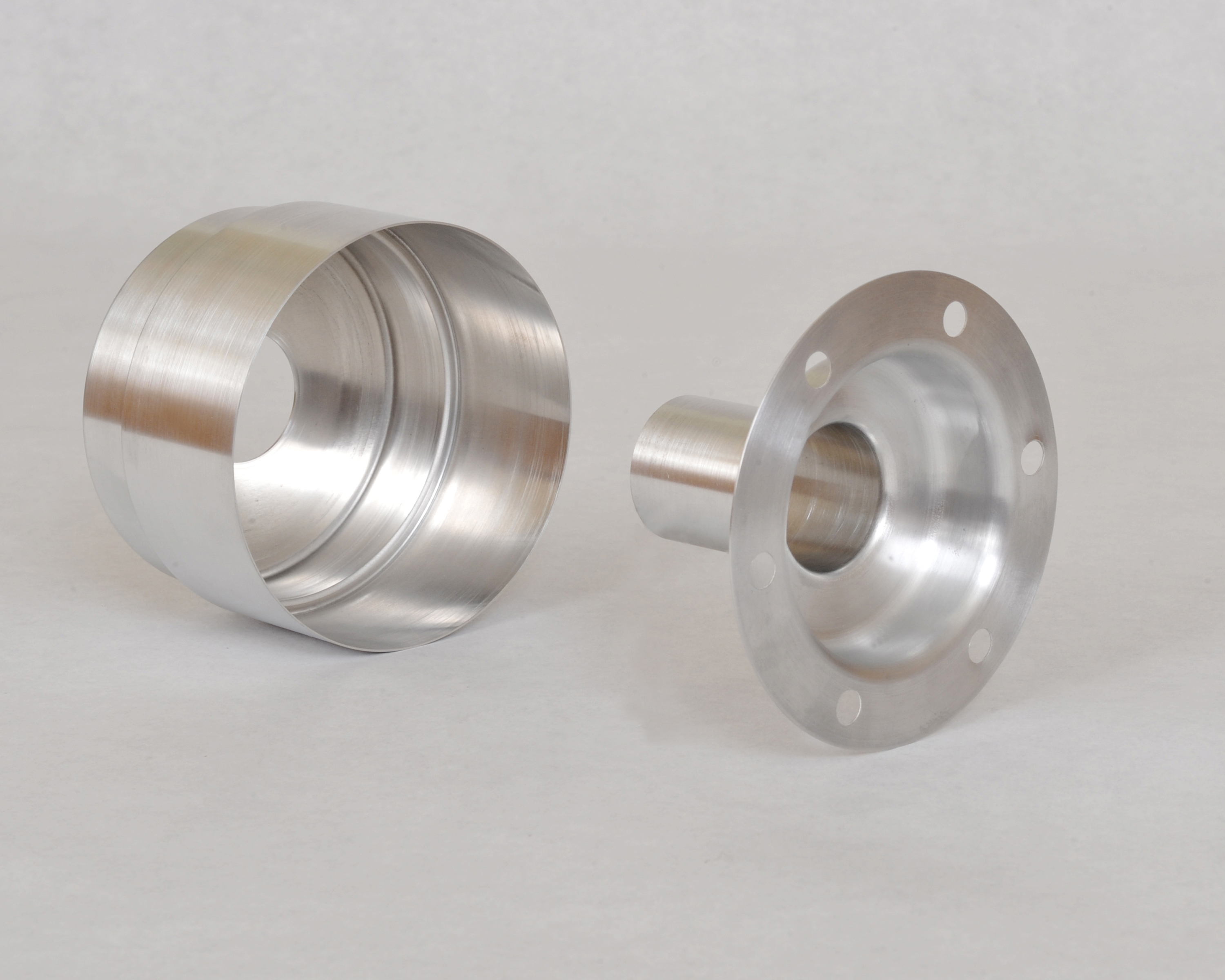

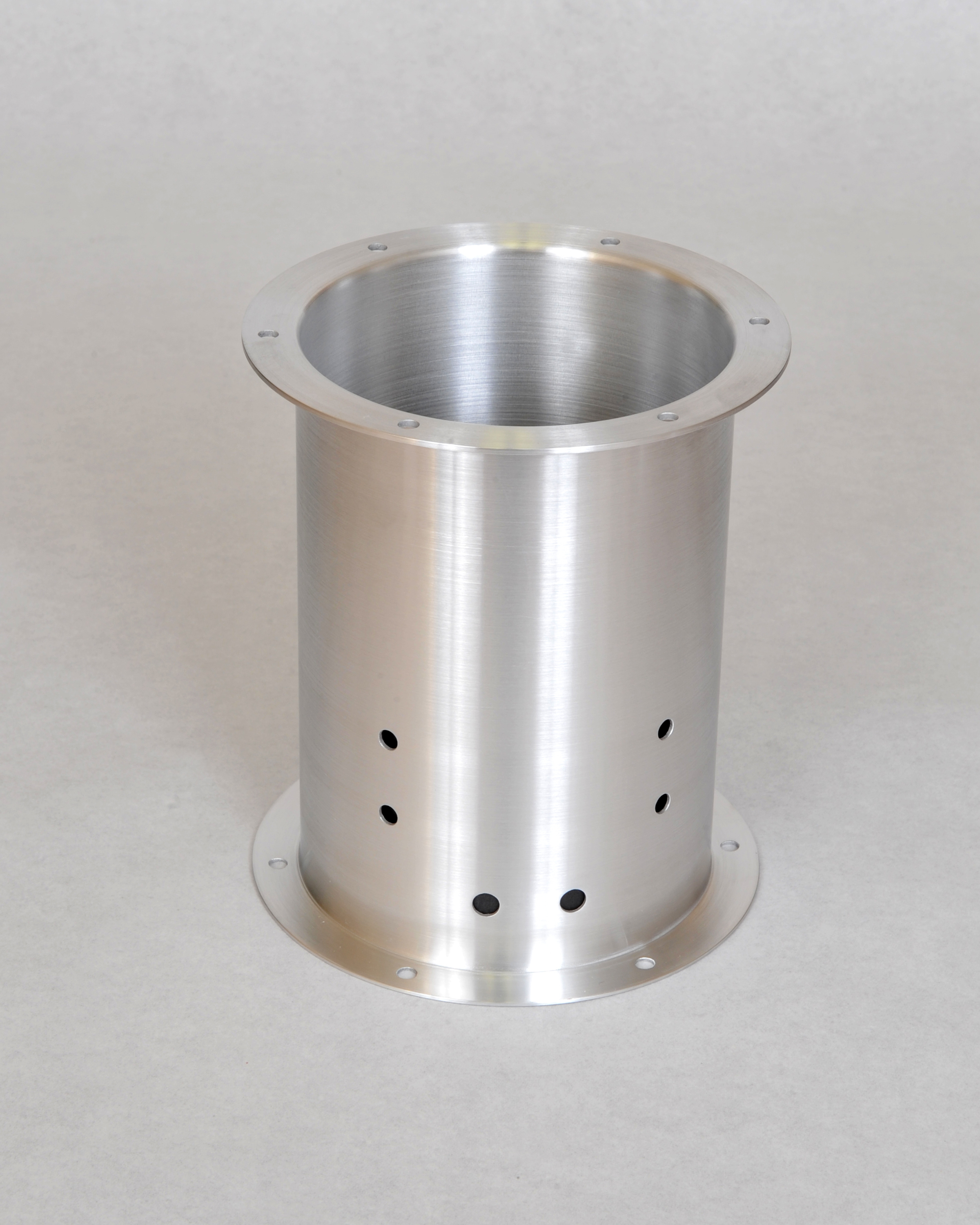

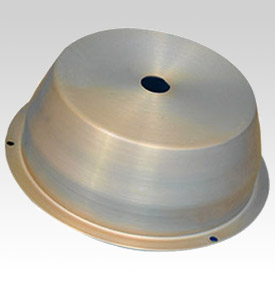

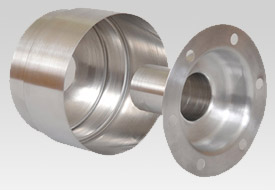

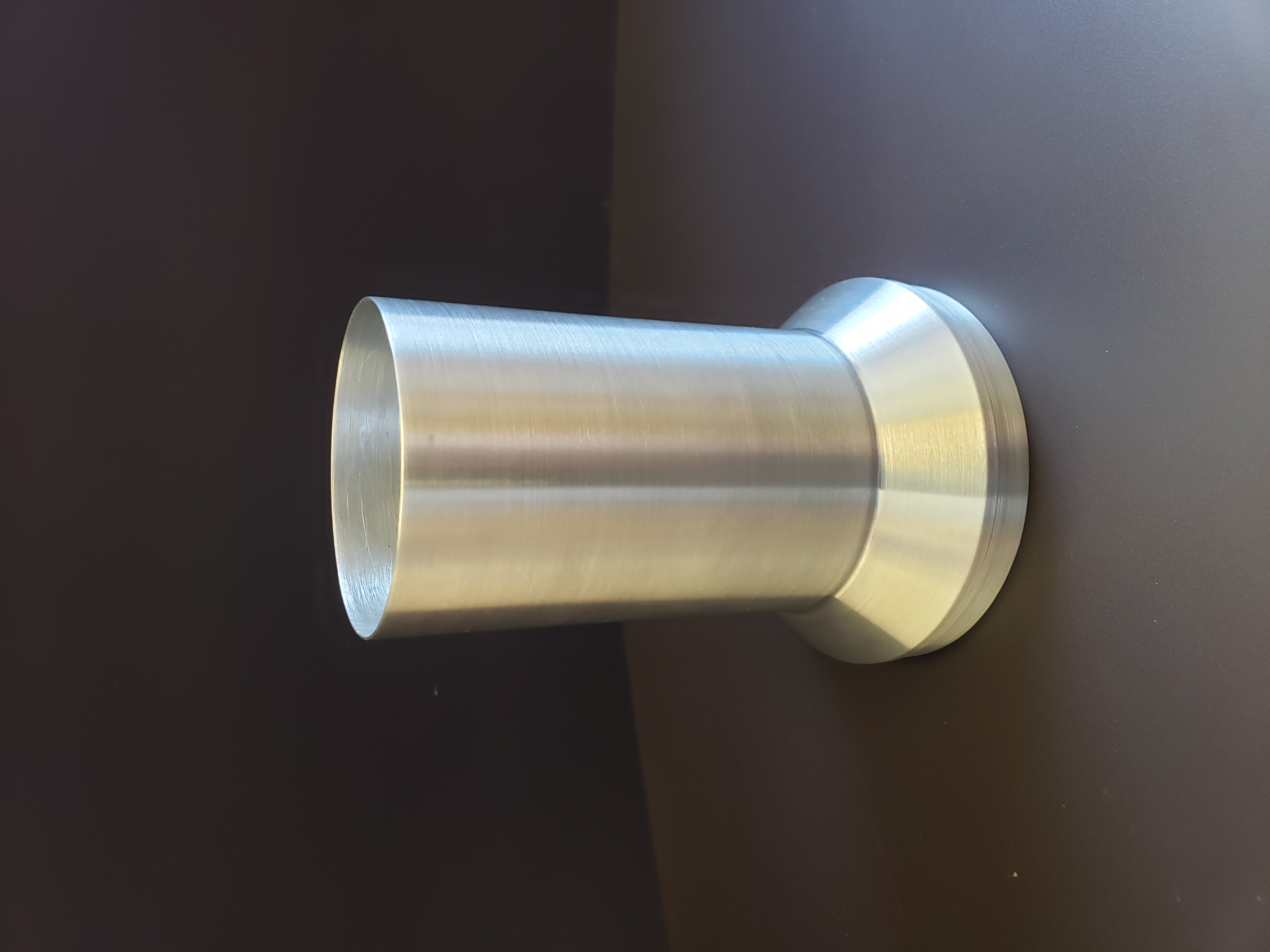

At Elyria Metal Spinning, we provide metal spinning and fabrication services to customers in a wide range of industries. From decorative to high precision, metal spinning is an efficient way to produce a variety of products including air handling and heat components, aerospace components and lighting fixtures. We work aluminum, steel, stainless steel, copper and brass components from 0.25" to 48" in diameter and are able to hold inner diameter tolerances to within ±0.002". Because the spinning process does not require expensive dedicated tooling, it is cost effective for low to high volume production work.

While many metal spinners provide only spinning services, we offer a comprehensive range of additional fabrication processes including drilling, laser cutting, welding, polishing and coating.

As a family owned company with 50 years of industry experience, our approach to business has always been centered on customer satisfaction. The value added fabrication, finishing, and inspection services we offer represent this commitment.

Dimensional inspection is performed by portable CMM, optical comparator, and micrometers. Granite surface plates also allow us to check flatness. As a provider of components for the nuclear, aerospace, and defense industries, compliance with all applicable ISO and Mil-Spec standards can be maintained as specified. For more information about our metal spinning capabilities, see the table below, or contact us directly.