Portfolios

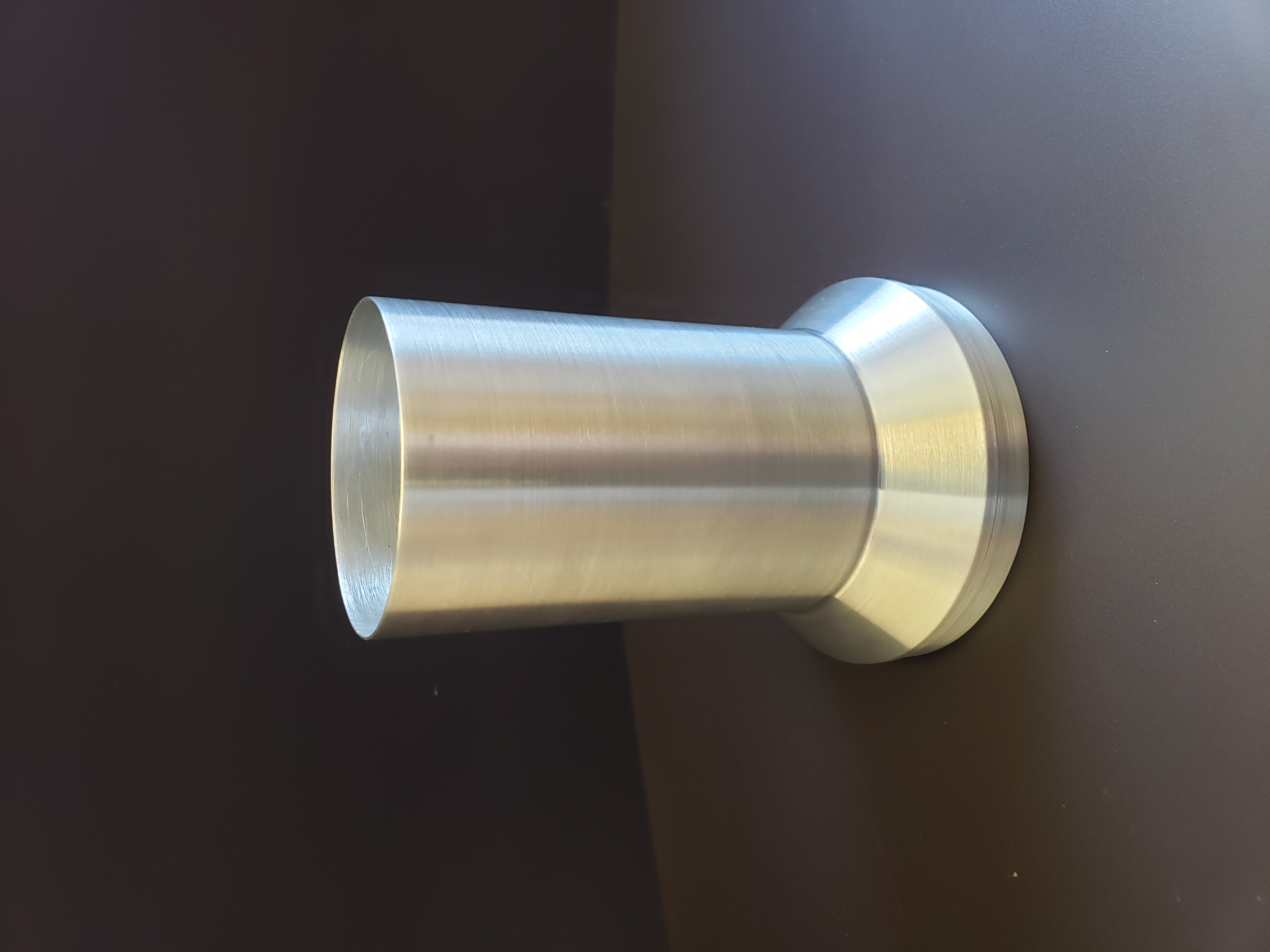

Scintillation Detection Light Shield Manufactured from Aluminum

| Project Name | Light Shield |

| Capabilities Applied/Processes |

Primary: Shear Material, Circle Cut, Spinning Secondary: CNC machining, inspection, cleaning and packaging |

| Material Finish | Machine polish using emery and scotch-brite |

| In Process Testing / Inspection Performed | Dimensional requirements |

| Industrial Use | Scintillation Detection |

| Delivery / Turnaround time | 3 - 4 weeks ARO |